Author: admin

-

Gas Springs vs. Traditional Springs: Advantages and Disadvantages

Gas springs, also known as gas struts, gas supports, or angle adjusters, are widely used industrial components that enable effortless lifting and lowering. Unlike traditional mechanical springs, gas springs provide significant advantages, particularly in industrial manufacturing. They find application in various fields such as automotive production, aviation, medical devices, furniture manufacturing, and mechanical engineering. Common…

-

The Unique Advantages of Controllable Gas Springs

In recent years, mold technology and manufacturing techniques have significantly advanced, driving the mold industry toward precision, efficiency, and extended product lifespan. Traditional elastic components used in molds, such as gas springs and rubber elements, have certain limitations during operation. For instance, gas springs and rubber components must be preloaded and can only deform up…

-

Gas Spring Lifetime Testing Method

The gas spring lifetime testing method involves assessing various performance metrics of gas springs under simulated operating conditions to determine their durability and functionality. Below is a comprehensive explanation of the method, including additional details regarding product performance and technical specifications. 1. Test Setup and Initial Measurements The gas spring is mounted vertically on a…

-

Gas Springs: Versatile Solutions for Various Industries

Introduction: A gas spring is a mechanical device that serves multiple functions, such as providing support, cushioning, braking, height adjustment, and angle control. Due to its versatility, gas springs have found widespread application across various industries, including medical equipment, automotive manufacturing, furniture design, textile machinery, and processing industries. Depending on their specific features and areas of…

-

Methods for Testing Gas Spring Force

Testing the lifting force of a gas spring is an essential step in determining its performance and suitability for specific applications. There are two primary methods for measuring the force of a gas spring: Method 1: Vertical Placement with a Load In this method, the gas spring is placed vertically on a flat surface. A…

-

5 Key Factors Leading to Gas Spring Damage

Gas springs are highly effective components used in various industrial and commercial applications. However, their lifespan and performance can be severely affected by improper handling and storage. To ensure optimal function and durability, several precautions should be observed during the use, storage, and transportation of gas springs. Below are the primary factors that contribute to…

-

Features of Gas Spring Shock Absorbers

Gas spring shock absorbers, which combine metal and rubber components, are designed to provide efficient vibration isolation and shock absorption in various mechanical systems. This type of shock absorber uses a large-diameter spring, enhancing its shock absorption capabilities compared to smaller diameter options. Additionally, it is equipped with adjustable bolts that allow for a height…

-

5 Key Factors for Evaluating the Quality of Gas Springs

When assessing the quality of a gas spring, several critical factors must be considered. These aspects directly impact the performance, reliability, and lifespan of the gas spring. Below is a detailed breakdown of these factors: 1. Sealing Performance The most fundamental aspect of a gas spring is its sealing performance. A well-designed gas spring must…

-

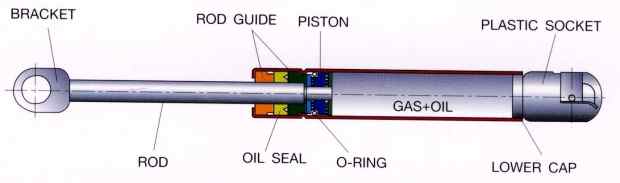

Working Principle of Support Gas Springs

Support gas springs, commonly used in automotive applications such as trunk lids, exhibit different behavior depending on temperature changes. These springs contain compressed gas and a sealing mechanism that plays a key role in their performance. Temperature Effects on Gas Springs When the temperature drops, the pressure inside the gas spring cylinder decreases. This reduction…

-

Gas Springs: An Essential Component in Modern Industries

Gas springs, also known as gas struts, are vital industrial components that provide support, cushioning, braking, height adjustment, and angle adjustment. Their versatility and performance make them essential in a wide range of applications. Commonly used in industries such as automotive, aerospace, medical devices, furniture, and machinery manufacturing, gas springs offer a controlled and reliable…