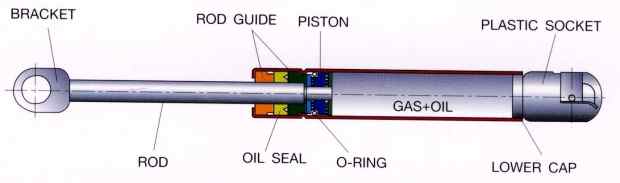

Support gas springs, commonly used in automotive applications such as trunk lids, exhibit different behavior depending on temperature changes. These springs contain compressed gas and a sealing mechanism that plays a key role in their performance.

Temperature Effects on Gas Springs

When the temperature drops, the pressure inside the gas spring cylinder decreases. This reduction in internal pressure leads to a gradual decrease in the force exerted by self-locking gas springs. As a result, the balance point between the gas spring and the trunk lid’s moment increases, meaning that the trunk lid may require manual assistance to open, particularly in colder temperatures. For example, at temperatures as low as -30°C to -40°C, the trunk lid may not automatically open and requires manual effort. This is a normal characteristic of gas springs and not a defect.

In contrast, during hot weather, the gas inside the spring expands due to thermal expansion, increasing the internal pressure. Under these conditions, the gas spring may lift the trunk lid with little to no manual effort. This explains why the trunk can be easily opened with a light push in summer, whereas it requires a higher lifting point in winter. This variation in performance is not caused by gas leakage but rather the natural expansion and contraction of the gas inside the spring.

Grease on the Gas Spring – Not Leakage

A common observation during gas spring use is the presence of grease on the surface. This is often mistaken for oil leakage but is, in fact, a result of the design. The piston rod and dust cover of the gas spring are fitted tightly to prevent dust and contaminants from entering the cylinder. During the extension of the piston rod, some of the lubricating oil in the guide block is pulled out, while during compression, the oil film is blocked outside the dust cover, preventing it from flowing back inside.

Over time, repeated compression and extension cycles cause more oil to accumulate on the surface of the dust cover, resulting in an oily film. This is a normal occurrence and should not be mistaken for a malfunction. The grease plays a crucial role in ensuring smooth operation and protecting internal components from wear and contamination.

Core Components and Maintenance of Self-locking Gas Springs

The core component of a self-locking gas spring is the gas seal. This seal serves as a barrier to prevent the leakage of gas and oil from the cylinder. The seal achieves its function through an interference fit with the piston rod. However, if paint residue or foreign substances adhere to the inner lip of the seal (the point of contact between the seal and the piston rod), the seal can become compromised, leading to the formation of a leakage path. Over time, this may result in slow gas leakage, reducing the spring’s effectiveness.

To prevent this, it is crucial to avoid any damage to the piston rod during vehicle use and maintenance. Avoid wrapping it with tape or cloth, and ensure the rod is not scratched or dented. Even minor damage to the piston rod can cause the gas spring to fail prematurely.

Types of Gas Spring End Fittings

Self-locking gas springs come with several types of end fittings, including:

- Single plate

- Single ear

- Double ear

- Universal ball head

The selection of an appropriate end fitting depends on the specific installation requirements and the specifications of the gas spring. Universal ball head fittings are often recommended due to their ability to automatically adjust the connection angle during operation. This adjustment helps eliminate lateral forces on the gas spring, particularly in installations where high precision is required.

Regardless of the type of fitting chosen, it is important to ensure that the gas spring allows the trunk lid or cover to open and close smoothly without interference or jamming. Proper installation and fitting selection are key to ensuring optimal performance and longevity of the gas spring system.

Conclusion

Understanding the operational principles and maintenance needs of self-locking gas springs is essential for ensuring their effective use in automotive and other applications. By choosing the right fittings, avoiding damage to the piston rod, and recognizing normal temperature-related behavior, gas springs can provide reliable and long-lasting performance.