Introduction to Gas Springs

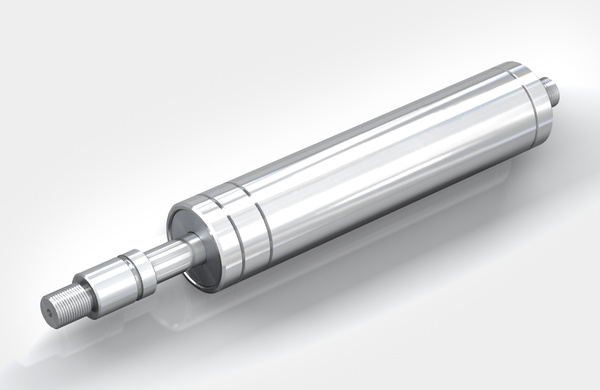

Gas springs are mechanical devices used in various applications to provide controlled motion, damping, and support. There are different types of gas springs, including compression gas springs and controllable gas springs, which are distinct in their functions and designs. Both types are common in industrial and consumer products, and a clear understanding of their characteristics is essential for those working with these technologies.

This article will focus on controllable gas springs, providing detailed insights into their functionality, key differences from other types of gas springs, and their operational applications.

1. Controllable Gas Springs vs. Lockable Gas Springs

At first glance, controllable gas springs might seem similar to lockable gas springs due to their shared categorization under gas springs. However, they are fundamentally different in design and purpose. From a professional standpoint, controllable gas springs have an adjustable mechanism that allows for precision control over their operation, while lockable gas springs are designed to hold a specific position once engaged.

Controllable gas springs are often equipped with a valve at the piston rod end, which allows users to regulate the movement of the piston using a control lever or other external tools. This mechanism enables precise adjustment of the spring’s force, making it ideal for applications requiring variable control of movement, such as in adjustable furniture, medical equipment, or industrial machinery.

In contrast, lockable gas springs are typically used when a firm and steady positioning is needed, such as in office chairs, hatches, and overhead storage doors. These springs lock into place, ensuring the supported object remains in a fixed position until the lock is released.

2. Self-Locking Gas Springs vs. Controllable Gas Springs

A self-locking gas spring is another type of gas spring, differing significantly from controllable gas springs. Self-locking gas springs require a release system to allow movement, meaning they lock automatically when no external force is applied. They are used in situations where stability and holding force are paramount, such as in automotive applications or heavy industrial equipment.

In comparison, a controllable gas spring does not automatically lock but relies on a user-activated control mechanism. The piston rod of a controllable gas spring is fitted with a valve that can be engaged using a wrench or lever, allowing for smoother and more controlled operation across a range of motion.

3. Nitrogen Springs and Their Relationship to Controllable Gas Springs

A nitrogen spring operates on a different principle compared to gas springs like controllable gas springs. Nitrogen springs are high-pressure devices commonly used in die-cutting and stamping applications. Although they are often confused with gas springs due to their similar operation involving compressed gas, they belong to a distinct category and serve different purposes.

Nitrogen springs are filled with high-pressure nitrogen and are known for their strength, longevity, and ability to deliver constant force over long periods. However, they are not considered part of the controllable gas spring family since they lack the adjustability and control features that define controllable gas springs.

4. Controllable Gas Springs in Practical Applications

Controllable gas springs are highly versatile and can be controlled in two primary ways:

- Cable-operated control: This type of spring uses a control cable attached to the piston rod valve. Pulling the cable allows the user to adjust the force or movement of the spring.

- Lever-operated control: A manual lever can be directly connected to the piston rod’s valve. When the lever is engaged, it allows for real-time adjustment of the spring’s force and movement.

The choice between these control methods depends on the specific application and user requirements. In industries like automotive, aerospace, or industrial manufacturing, controllable gas springs are vital in precision-driven applications where the need to adjust the motion or force of the spring in real-time is critical.

5. Air Springs vs. Controllable Gas Springs

An air spring, although similar in name, operates differently from a controllable gas spring. Air springs are sealed containers filled with compressed air, which provides the spring force through the compression of air rather than a piston-rod mechanism like in gas springs. Air springs are known for their non-linear elastic characteristics, making them ideal for suspension systems, where smooth and progressive damping is required, such as in vehicle suspensions and heavy machinery.

Despite their use of gas (air), air springs do not fall under the controllable gas spring category because they function in a fundamentally different manner. While both types of springs provide damping and force control, they are suited to different applications based on their mechanical properties.

Conclusion

Controllable gas springs are specialized devices designed for applications requiring precise movement control and adjustability. Their ability to be manually controlled or operated through a cable makes them suitable for a variety of dynamic applications across industries. Understanding the differences between controllable gas springs and other related devices like lockable, self-locking, nitrogen, and air springs is crucial for selecting the right component for a specific use case.

Their adaptability and fine control over motion make controllable gas springs invaluable in fields ranging from medical equipment to industrial machinery, where the balance between movement and stability is key.