Gas springs, especially support gas springs, are a crucial component in many industrial applications, designed to provide controlled force and motion. One of the key elements within these springs is the support rod, which plays a pivotal role in ensuring the proper function of the system. This document explores the function of the support rod in gas springs and provides a technical overview of how it operates.

Structure and Working Principle

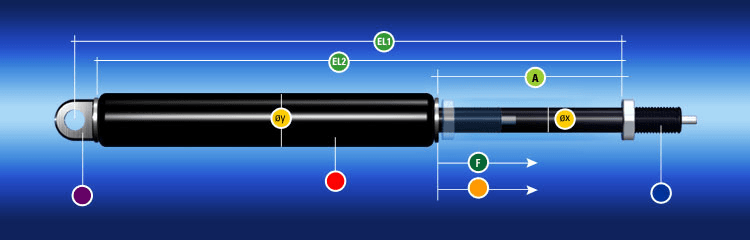

A gas spring, including the support type, operates using a combination of gas (typically nitrogen) and liquid as the working medium. The main components of a support gas spring include:

- Pressure tube

- Piston

- Piston rod (support rod)

- Various connecting parts

The internal mechanism of a support gas spring is based on high-pressure nitrogen gas sealed within the cylinder. A key feature of this design is the piston, which contains a small through-hole that allows gas to pass between both sides of the piston. The pressure on both sides of the piston is equal; however, the surface area on either side differs due to the presence of the support rod on one side. This difference in surface area results in a net force, pushing the piston towards the side with the smaller area—the side where the support rod is located.

This mechanism generates the spring force of the support rod, which can be customized by adjusting variables such as:

- The pressure of the nitrogen gas

- The diameter of the piston rod

Elasticity Characteristics

Unlike traditional mechanical springs, support gas springs feature an almost linear elasticity curve. This linearity makes them ideal for applications where precise and predictable force is required. The elastic coefficient (X) of a standard support rod typically falls between 1.2 and 1.4. These parameters, including the spring force and elasticity, can be flexibly defined to meet specific operational needs and environmental conditions.

Comparison with Mechanical Springs

While both mechanical and gas springs are used to store and release energy, support gas springs offer several advantages over traditional mechanical springs:

- Adjustability: The force exerted by a gas spring can be precisely tuned by adjusting the gas pressure or the rod diameter, allowing for more versatile and application-specific solutions.

- Linear Force Output: Gas springs provide a near-linear force output, making them highly predictable compared to the nonlinear behavior of mechanical springs.

- Damping Capability: Gas springs can also offer damping effects, which can help in controlling motion, unlike traditional mechanical springs that merely provide force.

Customization for Different Applications

Support rods and gas springs can be customized for various applications based on factors like:

- Operating temperature

- Load capacity

- Stroke length

- Corrosion resistance

These customizations ensure that gas springs are suited for a wide range of industries, from automotive to aerospace, where precise force control and durability are critical.

Conclusion

Support rods in gas springs are an integral part of the system, responsible for generating the necessary force to support, lift, or balance various loads. Their design, which includes a high-pressure nitrogen chamber and a piston with unequal surface areas, provides a reliable and adjustable force output. By offering a near-linear elasticity curve and the ability to customize various parameters, gas springs have become an indispensable tool in numerous technical applications.